Heat Your Patio in Style with Infratech Motif Collection

**Heat Your Patio in Style with Infratech Motif Collection**

Posted: May 09, 2023 at 08:44 PM | 6 minute read

Heaters

When it comes to outdoor heating, the old days of boring, generic patio heaters are long gone. Today, you can find stylish and functional options that not only keep your space warm but also enhance its overall look. The Infratech Motif Collection is a perfect example of how modern technology and design can come together to create something truly exceptional.

Infratech has always been a trusted name in the HVAC industry, known for producing high-quality, durable infrared heaters. But now, they’ve taken their offerings a step further with the Motif Collection. This new line allows users to choose from a variety of styles and finishes, making it easier than ever to match your heater with your outdoor decor.

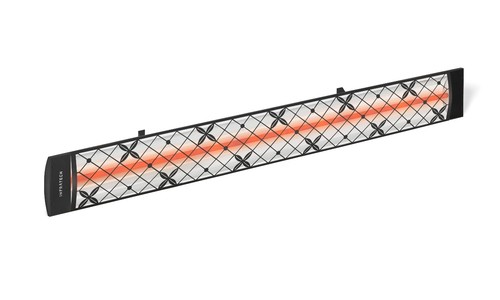

The Motif Collection includes four distinct designs—Contemporary, Craftsman, Mediterranean, and Traditional—each offering a unique aesthetic. Whether you're looking for sleek, modern lines or classic, traditional patterns, there's something for every taste. These heaters are available in both residential and commercial versions, with multiple sizes, wattages, and voltage options to suit different needs.

One of the standout features of the Motif Collection is its versatility. You can mix and match different styles within the same space, ensuring a cohesive yet personalized look. Plus, because all models are made by Infratech, they’re designed to work seamlessly together, whether you're adding a single unit or expanding your heating system.

Each model in the Motif Collection uses infrared technology, which is highly efficient and provides even, comfortable heat without the harsh glare or intrusive light found in some competing products. The medium-wave quartz elements used by Infratech deliver a soft, warm glow that enhances the ambiance of your outdoor area.

In addition to their visual appeal, these heaters are built to last. With an expected lifespan of nearly 5,000 hours, they offer long-term value and performance. And when maintenance is needed, Infratech makes it easy to replace components safely and efficiently.

Whether you're hosting friends, running a business, or simply enjoying your backyard, the Infratech Motif Collection offers the perfect blend of style and functionality. It’s more than just a heater—it’s an investment in comfort, aesthetics, and quality.

If you're looking to upgrade your outdoor space and add a touch of elegance, consider the Infratech Motif Collection. Not only will it keep you warm, but it will also elevate your entire patio or deck design.

Want to learn more or have questions? Reach out today—we’d be happy to help!

Induction heat treatment system is an advanced metal material heat treatment process that uses the principle of electromagnetic induction to heat metal materials, changing their microstructure and improving their physical and mechanical properties. This system is widely used in multiple industries such as steel, aviation, automotive, and machinery manufacturing, and plays an irreplaceable role in improving material hardness, wear resistance, toughness, and other aspects.

working principle

The core of induction heat treatment system lies in electromagnetic induction heating. When an alternating current passes through an induction coil, an alternating magnetic field is generated around the coil. Metal workpieces placed near the coil will generate eddy currents, known as induced currents, under the action of this magnetic field. When this current flows inside the workpiece, it generates heat, causing the workpiece to be heated. By controlling the current frequency, power, heating time, and cooling method, it is possible to accurately perform heat treatment on the workpiece, such as surface quenching, tempering, annealing, normalizing, etc.

system composition

A complete induction heat treatment system mainly includes the following parts:

Induction heater: generates an alternating magnetic field to heat the workpiece.

Power supply: Provides electrical support for induction heaters.

Control system: Monitor and adjust various parameters of the heating process to ensure the effectiveness of heat treatment.

Cooling system: used to control the cooling rate of the heated workpiece and complete the heat treatment cycle.

Fixture: Fix the workpiece to the optimal heating position.

Characteristics and advantages

1. Precise control: By precisely adjusting parameters such as current and frequency, precise control of heating depth and temperature can be achieved.

2. Efficient and fast: Induction heating has a fast speed and can heat up to the desired temperature in a very short time, shortening the heat treatment cycle.

3. Energy saving and environmental protection: There is no open flame during the heating process, which saves a lot of energy compared to traditional furnaces, and there are no harmful substance emissions.

4. Local heating: It can heat specific parts of the component to avoid resource waste and deformation caused by overall heating.

Application Cases

Automotive manufacturing: used for surface quenching of components such as gears, connecting rods, crankshafts, etc., to improve their hardness and wear resistance.

Aerospace: Heat treatment of key components such as aircraft landing gear and engine blades to enhance their fatigue resistance.

Mechanical manufacturing: Quenching treatment of cutting tools, molds, etc. to extend their service life.

Oil extraction: Heat treatment of parts such as drill bits and pipeline joints to improve corrosion resistance and mechanical strength.

conclusion

Induction heat treatment systems play an indispensable role in modern industry through their efficient heating capacity and precise control mechanism. With the continuous advancement of technology, induction heat treatment systems are developing towards smarter and more energy-efficient directions, and more application scenarios will be developed in the future.

Induction hardening, heating equipment, quenching equipment,, induction heating

Ningbo Dedao Electronic Technology Co., Ltd , https://www.nbdedao.com