Our Xiamen Zhong Li Da Machinery Co., Ltd has been specializing in precision machining parts, CNC machining parts, custom CNC machining based on customer drawings since 1995. With over 25 years of experience, we provide high-quality, reliable solutions for a wide range of industries. Product Details We have extensive experience in manufacturing micro parts for various sectors, including but not limited to: Turning Parts, Shafts, Machining Parts, CNC Machining Parts, Milling Parts, Hardware Accessories, Arrow Metal Parts, Special Fasteners, and Industrial Control Switch Metal Parts used in medical, electronic, fiber optic, and microwave fields, among others. FAQ Q: How soon can I get a reply after sending an inquiry? A: All inquiries will be replied within two hours, except during sleeping time in China. Our phone lines are always open for any calls at any time. Q: How soon can I get samples? A: Samples are usually sent out within 7 working days after the product drawing is confirmed by both parties. Q: What file formats do you accept for my products? A: We accept various formats such as IGS, STEP, STP, JPG, PDF, DWG, DXF, and more. If you don’t have a CAD file, we can also accept a scan of a hand-drawn design. Q: What if I don't have a drawing? How can I get a sample? A: If you don’t have a drawing, you can send us a sample, and we’ll scan it to create 2D and 3D drawings first, then produce the sample for you. Q: What are the common materials you use in your projects? A: Aluminum, Stainless Steel, Carbon Steel, Copper, Plastics, Titanium, and PEEK are some of the commonly used materials. Q: What is your MOQ (Minimum Order Quantity)? A: We don’t have a minimum order quantity. You’re welcome to place a trial order to test our quality and service. Q: What payment terms do you accept? A: EXW/FOB Xiamen, paid via T/T, PayPal, or Western Union. Q: What kind of machining do you excel in? A: We specialize in all kinds of machining parts. Miniature Ball Screws,Lead Screw Backdrive,Back Drive Ball Screw,Miniature Ball Screw Assembly Suzhou Industrial Park Hojama Technology Co., Ltd , https://www.hojama-tech.com

CNC Center Milling Service

CNC Machining/Turning/Grinding Service  Â

Automatic Lathe Service

Quality Assurance

ISO9001:2008 Certified

Materials

Aluminum Alloy: 5052 / 6061 / 6063 / 2017 / 7075 / ADC12 / 518, etc.

Brass Alloy: 3600 / 3602 / 2604 / H59 / H62, etc.

Stainless Steel Alloy: 303 / 304 / 316 / 412, etc.

Steel Alloy: C45

Carbon Steel: 12L14 / 12L15 / Die Steel / Spring Steel, etc.

Special Materials: Lucite / Nylon / Bakelite / POM / ABS / PP / PC / PE / PEEK / Titanium, etc.

We can handle many other types of materials. Please contact us if your required material is not listed above.

Surface Treatment

Blackening, polishing, sandblasting, anodizing, chrome plating, zinc plating, pickling & passivation, vibration, nickel plating, tinting

Inspection

Mitutoyo three-coordinate measuring machine / Mitutoyo Tool Microscope, can measure up to 300mmX x 175mmY x 220mmZ

File Formats

Solid Works, Pro/Engineer, AutoCAD (DXF, DWG), PDF, TIF, IGS, STP, etc.

Production Flow Chart

Factory Show

Shipping & Payment

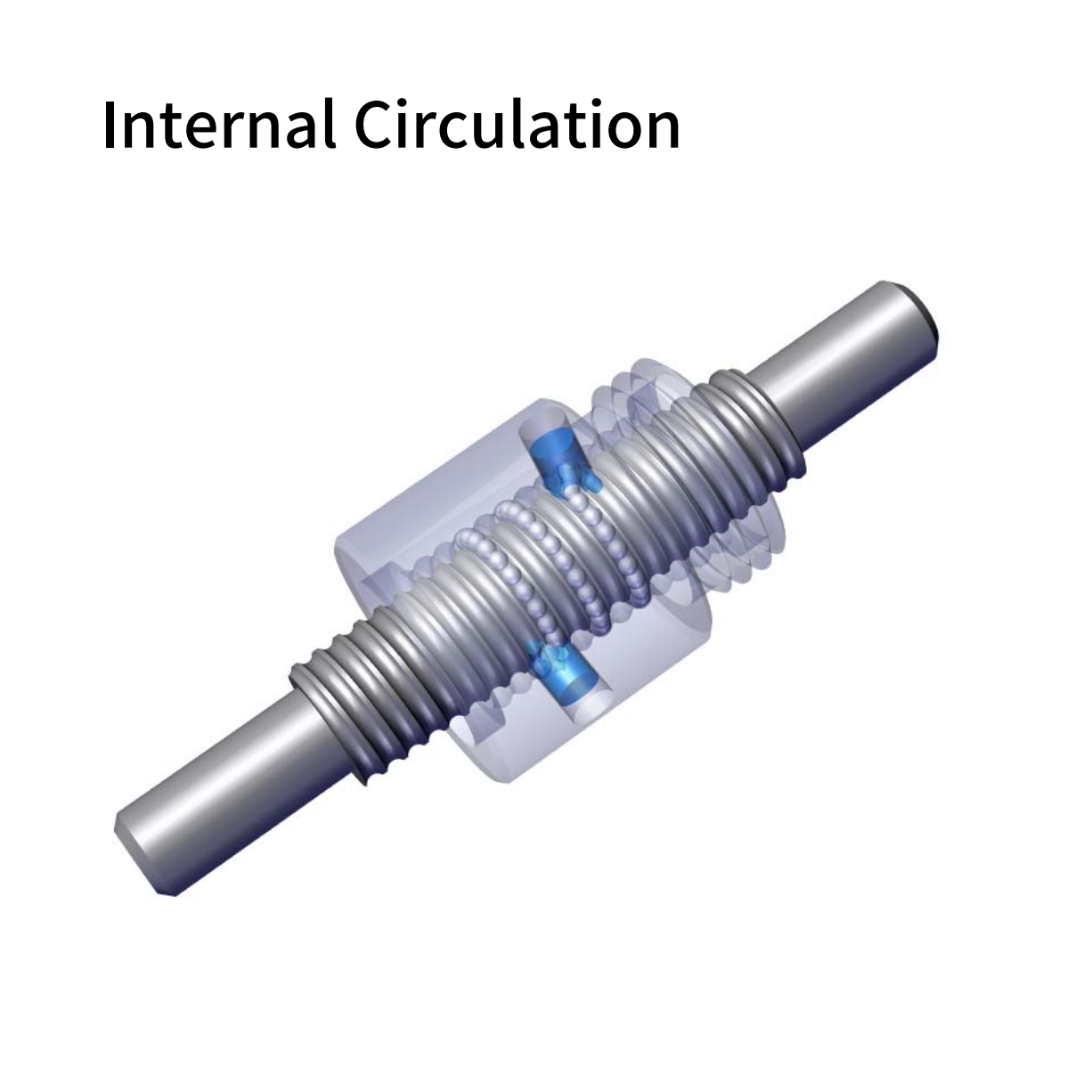

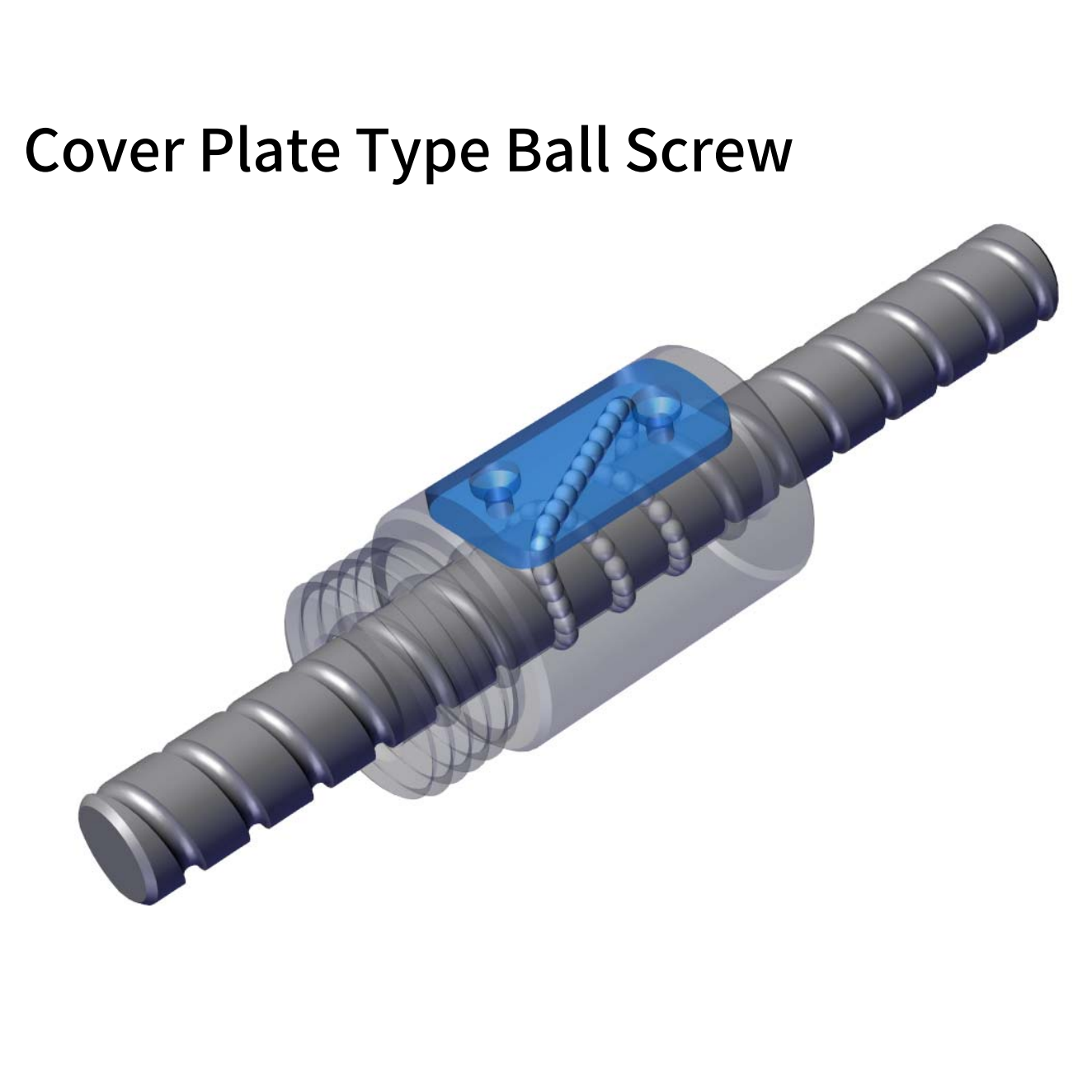

Miniature ball screws--Hojama precision ground ball screws

Anti-rust treatment for ball screws:

I. Surface pretreatment of the objects to be rust-proofed

II. Application of anti-rust oil

OEM&ODM Flat Head Copper Rivets Solid Brass Rivet 3mm-10mm Diameter

Model NO.: Custom

Micro Machining: Yes

Equipment: CNC Lathe, etc.

Surface Treatment: Pickling and Heat Treatment

Technology: Machining, Turning, Broaching, Drilling

Delivery: FedEx, DHL, UPS, TNT or as per your preference

MOQ: 100 pieces

Lead Time: 7~15 days

Trademark: ZLD

Transport Package: PE Bag + Carton + Box

Specification: Non-standard

Origin: Xiamen, Fujian, China

Â

Diameter: 4mm-16mm

Machining method: Ground

Material: Bearing steel and stainless steel are recommended.

Precision Grade: C3 and C5. The repeatability position accuracy can be achieved up to 8μm.

Â

Â

1. Surface cleaning: An appropriate cleaning method must be selected based on the surface properties of the objects to be rust-proofed and the actual conditions. Commonly used methods include solvent cleaning, chemical treatment cleaning, and mechanical cleaning.

Â

2. Surface drying: After thorough cleaning, the surface can be dried with filtered dry compressed air, or in a dryer at 120~170℃, or wiped dry with clean gauze.

Â

1. Immersion method: Small-sized items are immersed in anti-rust grease to allow a layer of anti-rust grease to adhere to their surfaces. The thickness of the oil film can be controlled by adjusting the temperature or viscosity of the anti-rust grease.

Â

2. Spraying method: For large-sized rust-proof objects that cannot be treated by immersion, spraying is generally performed with filtered compressed air at a pressure of approximately 0.7MPa in a clean-air environment. This method is suitable for solvent-diluted anti-rust oil or thin-layer anti-rust oil, but complete fire prevention and labor protection measures must be implemented.

Â

3. Brushing method: Applicable to outdoor construction equipment or products with special shapes that are not suitable for immersion or spraying. When brushing ball screws, care must be taken to avoid grease accumulation and prevent missed coating.

Â

Hojama is famous for the high-precision ball screw manufacturing. For the mini size ball screw, we can provide customization support on dimensions, materials, surface treatments, and more. Just provide us with the product drawing, and we can offer you not only a high-quality product but also considerate service.

Â

Â